GET UP TO SPEED ON HOW TO CHECK YOUR ROPE SO YOU CAN MAKE SURE IT’S IN PERFECT WORKING ORDER OR IF IT’S TIME TO INVEST IN A NEWER MODEL.

By Matt Gordon

Your rope is one of the most important parts of your climbing experience, whether you’re having a long top rope session or projecting on lead. At Mesa Rim we check all of our ropes on a regular basis so we have you covered there.

But, when was the last time you checked your personal rope and ensured that it’s safe to climb on?

Sterling, a leading climbing rope manufacturer gives general guidelines for rope life at 1 year with extensive (everyday) use, 5 years with regular to occasional use, and 10 years for a rarely-used rope. However, there is no guarantee for how long your rope will last due to the wide variety of factors that can contribute to rope deterioration.

This article will give you a better understanding of rope construction, how to check for wear and tear, storage tips, and more.

ROPE FOUNDATIONS

Understanding the basic construction of a climbing rope is the first step in knowing how to check yours. The standard style of climbing rope, known as kernmantle, was originally created by the German company Edelrid. Kernmantle ropes have two components: core (kern) and sheath (mantle).

Core

Sheath

The core is constructed from several strands of nylon that is braided or wrapped around one another; it’s the part of your rope that gives it the ability to withstand falls. The sheath of the rope is constructed with thinner, woven nylon and is designed to protect the core from damage and preserve the integrity of the rope.

CHECKING THE ROPE

The most basic rule to know when checking your rope is this: If you can see the core, retire it. Any visible core is vulnerable to significant and immediate damage and should not be climbed on. If you can’t see the core of your rope, that’s a good start. One way to inspect the integrity of the core is the pinch check. Pinch two nearby parts of your rope together. If the rope flattens to the point where the two strands are parallel, your rope is core-shot. This means the core of the rope is no longer strong enough to safely catch falls and should be retired. If there is space between the two strands of rope when pinching, the core of your rope is still acceptable for climbing.

To examine the sheath of your rope, run it through your hand while flaking it out to inspect for any deformities. These deformities can be cuts, burns, softness, bulges, and sheath slip.

Here’s a breakdown of those deformities:

CUT

Any cut that pierces through the sheath is grounds for rope retirement.

Cut

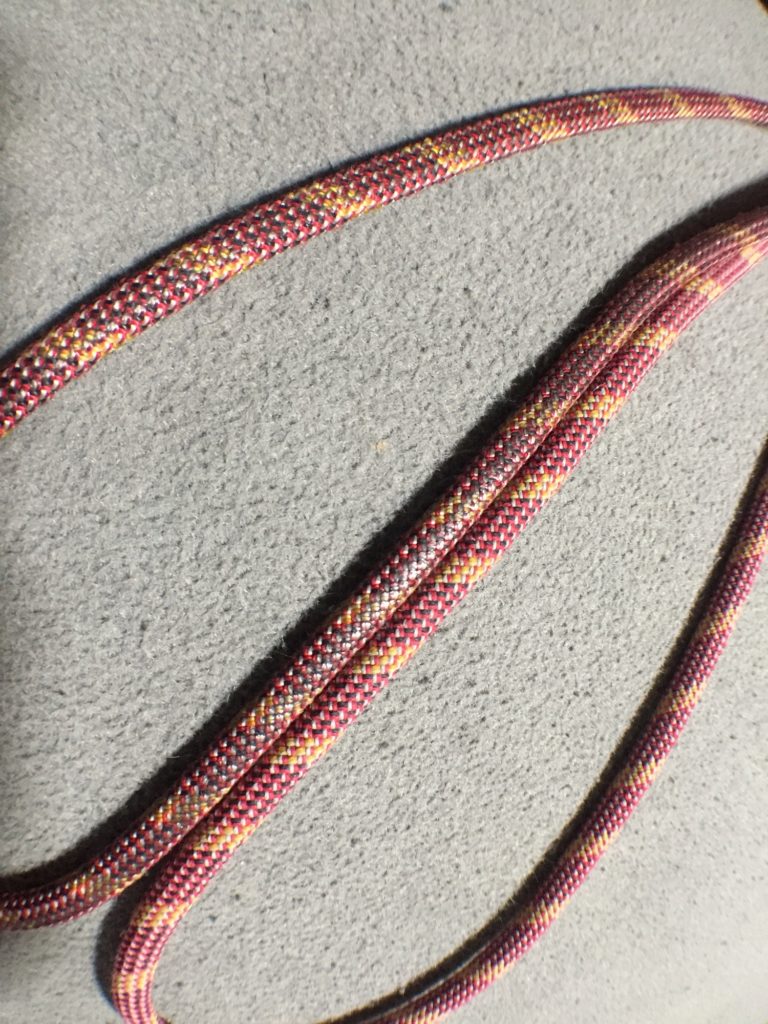

BURNS

Burns are often caused by heat friction from the rope passing through your belay device and anchor points. Minor glazing of the sheath from rope friction is acceptable, but take note of that point and monitor it closely. Significant glazing of the sheath can make it much more likely to tear, which is a good reason to replace the rope.

The top rope shows glazing or a bit of a sheen, which indicates that it’s suffered burning. The bottom rope is not burned.

SOFTNESS

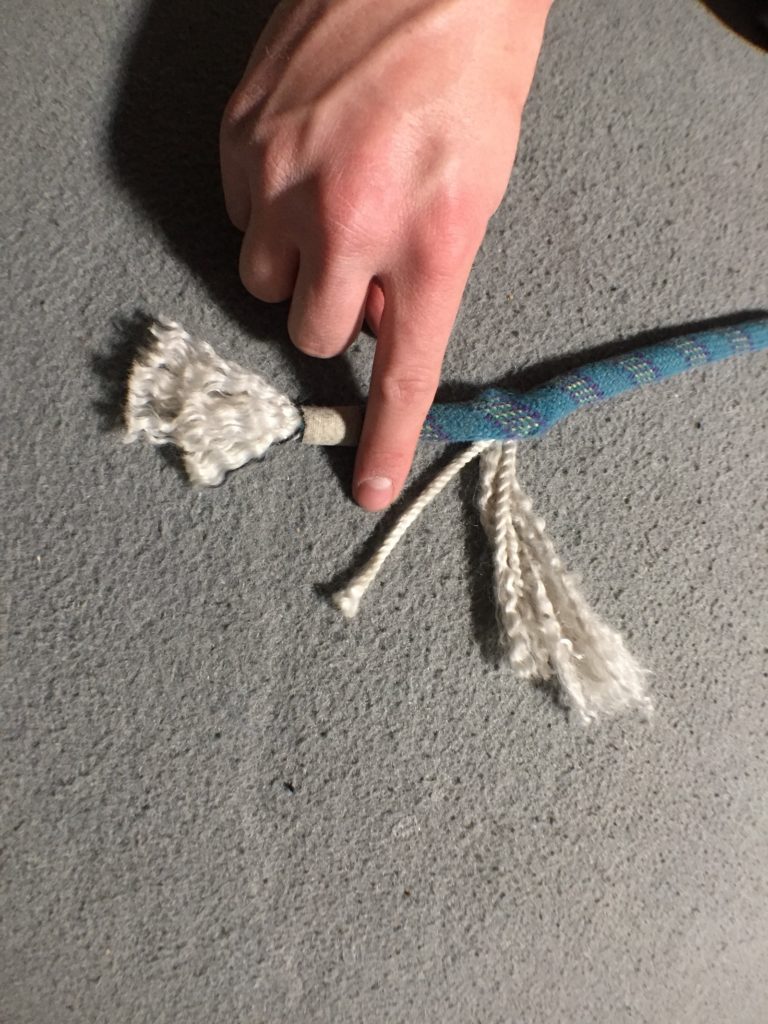

If you notice significant softness while flaking your rope, stop and do a pinch check on that part of the rope to ensure the core is intact.

This rope is softer than a feather. Time for a pinch test!

This rope is good to go!

It’s time to let it go, let it go!

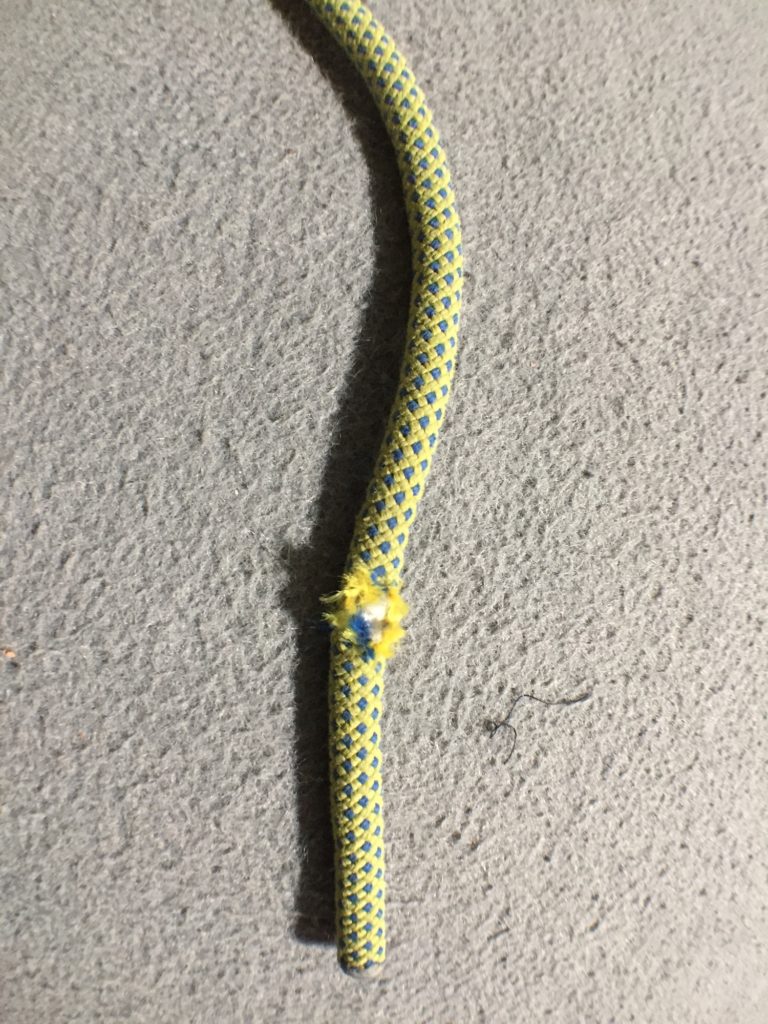

BULGE

A major bulge in the rope can be a sign of significant interior damage to the core and may warrant retiring.

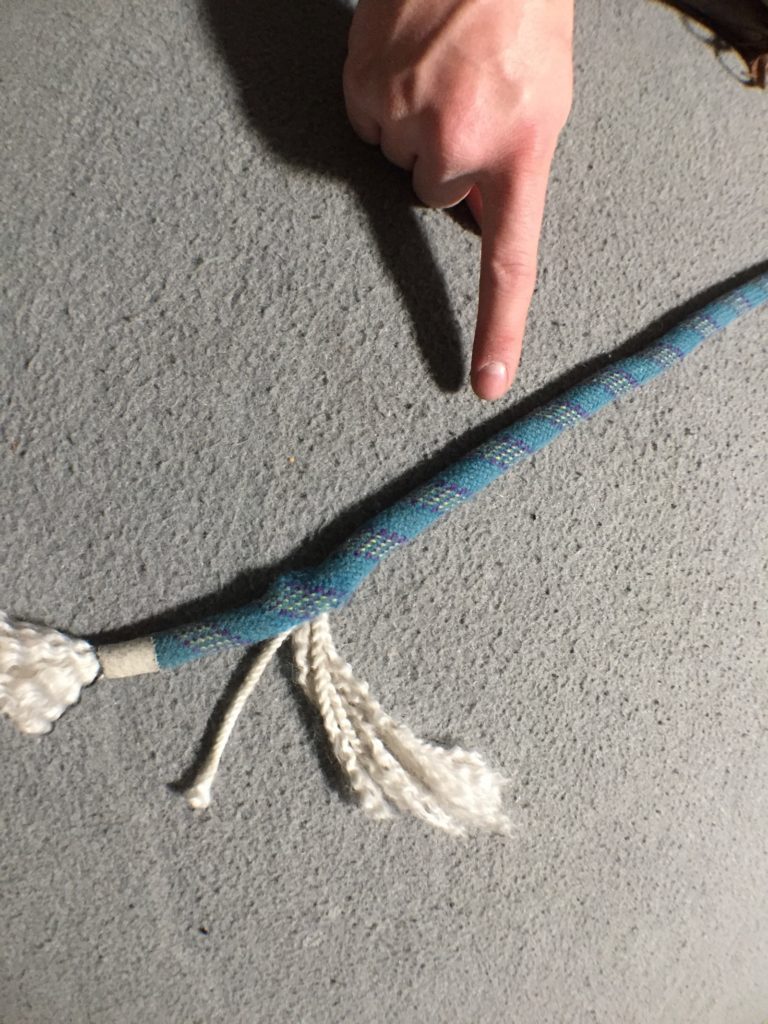

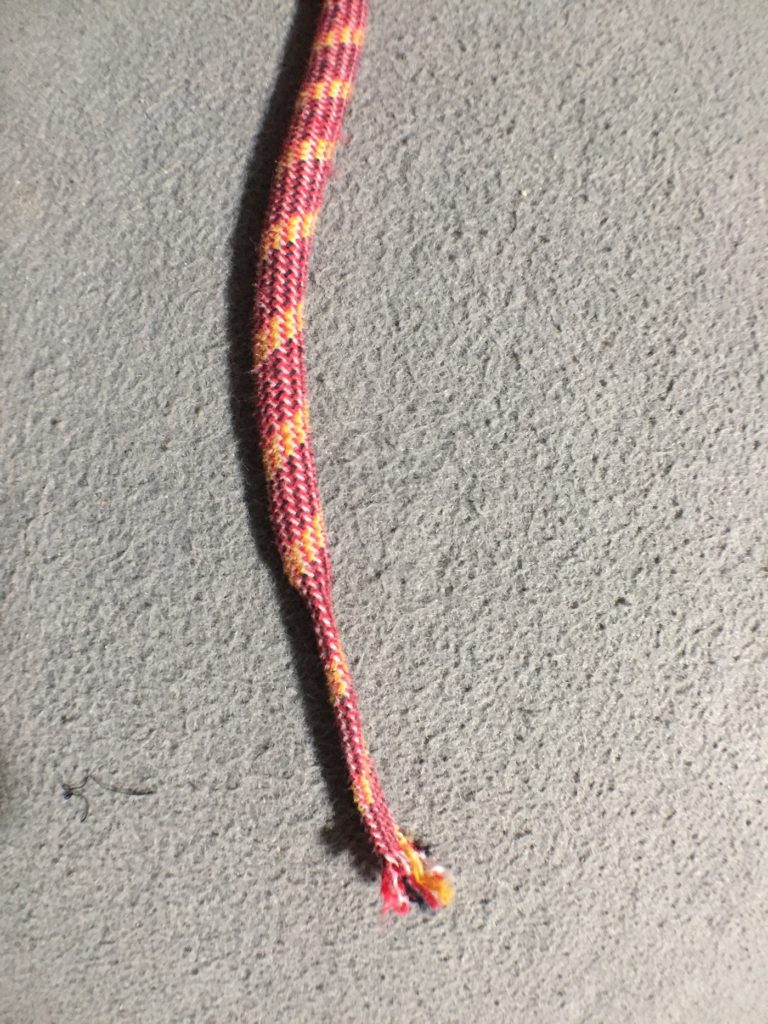

SHEATH SLIP

Finally, be mindful of sheath slip on your rope. Repeated use over time can cause the sheath of your rope to bunch up toward one end and potentially pull the core out of the opposite end. This creates a shoestring effect. If the shoestring is small and on the end of the belayer’s side of rope, it doesn’t pose an immediate safety risk because it isn’t inside of your climbing system. However, it’s a good idea to cut that end of the rope. If you do trim your rope for any reason, take note of the amount of rope you’re losing to avoid your rope becoming too short for your desired climbs. For example, if you were to cut 10 meters off of your 70-meter rope, it would no longer be of sufficient length for a 100-foot route. This also demonstrates the importance of tying a knot at the end of your rope as a last line of defense.

This sheath has slipped

STORAGE TIPS

One important way to maximize the life of your rope is proper storage. Do your best to keep your rope out of direct sunlight for long periods of time. Avoid extreme temperatures, keep your rope away from moisture, and coil your rope properly (see the rope coil tutorial video below). Also, avoid chemical exposure to your rope at all costs. Gasoline, car oil, and many other chemicals can be silent killers. The damage that these chemicals do to your rope is nearly undetectable and can fatally compromise the safety of your rope.

FINAL THOUGHTS

This article is designed to be a useful introduction to rope care and inspection, but is not definitive. It is important to consult the rope manufacturer’s guidelines and recommendations and take advantage of the many resources available within the climbing community.